With the popularity of water sports, inflatable boats are becoming more and more popular because of their easy storage and transportation. Whether used for recreational fishing, rafting or as a professional rescue tool, inflatable boats have demonstrated their reliability and practicality in different environments. One of the keys to enabling inflatable boats to cope with harsh water conditions is the inflatable boat fabric used.

Inflatable boat fabrics are mainly used for the outer layer of the hull. It must not only be able to withstand the internal and external pressure of the hull, but also have multiple properties such as waterproof, wear-resistant, UV-resistant and chemical-resistant. Its key features include:

Inflatable boats are inflated by air to maintain structural stability, so their fabrics must have excellent pressure resistance. The strength of the fabric directly determines how much pressure the hull can withstand when inflated, and it is not easy to deform or burst.

Inflatable boats are in the water for a long time, so the fabric must have extremely strong waterproof properties. Most modern inflatable boat fabrics use coating technology to ensure that their surface maintains a good waterproof effect, thereby avoiding water penetration and keeping the boat dry.

Inflatable boats usually travel on rough water surfaces, so their fabrics must be wear-resistant and able to withstand scratches from objects such as rocks and water plants. High-quality inflatable boat fabrics ensure that they are not easy to wear even in harsh environments for many years.

Long-term exposure to sunlight can easily cause fabrics to fade or become brittle. Therefore, inflatable boat fabrics must have UV resistance to ensure that they can be used in outdoor environments for a long time without losing performance.

Inflatable boat fabrics are made of a variety of materials, mainly divided into two categories: PVC fabrics and polyurethane (PU) fabrics.

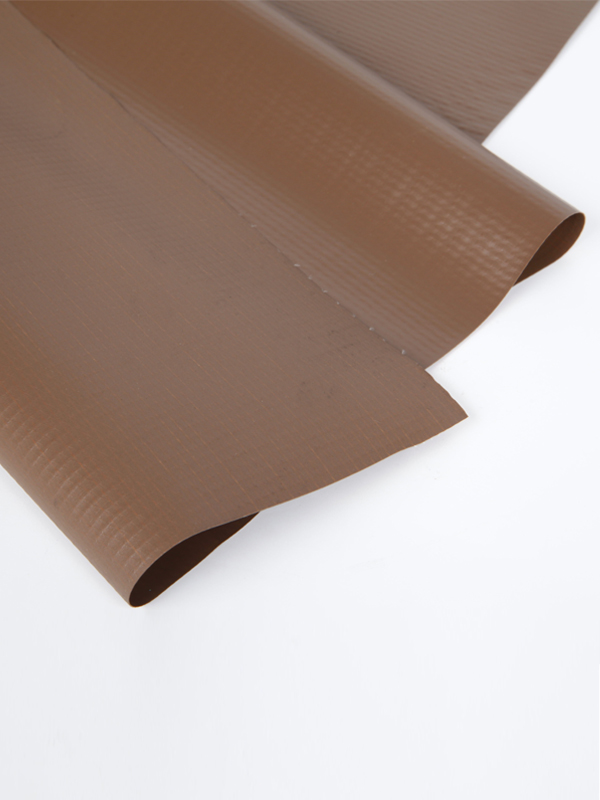

Polyvinyl chloride (PVC) fabrics are the most common material in inflatable boats. It has excellent water resistance and wear resistance, and has advantages in cost. PVC fabrics are usually made through a coating process, and the surface is coated with PVC resin, which enhances the strength and water resistance of the fabric. This material is commonly found in entry-level inflatable boats or lightweight inflatable boats.

Polyurethane fabrics are more environmentally friendly and softer than PVC materials, especially in low temperature environments, and are not easy to harden. PU fabrics are not only highly wear-resistant and weather-resistant, but are also generally superior to PVC materials in terms of UV resistance and pressure resistance, so they are widely used in high-end inflatable boats and professional boats.

In recent years, many inflatable boats have begun to use high-strength fiber materials such as high-density polyethylene (HDPE) or DuPont Kevlar fibers to improve the overall strength and impact resistance of the hull. These fibers have extremely high tensile strength and toughness, which can effectively improve the performance of inflatable boats in harsh waters.

The choice of inflatable boat fabric not only affects the durability of the hull, but also directly determines the use scenario of the boat. Different types of fabrics adapt to different usage needs:

For lightweight leisure inflatable boats, PVC fabrics have become the first choice for many consumers because of their economy and sufficient strength. These boats are usually used in calm lakes or oceans to carry light recreational activities, such as family leisure fishing or water rafting.

For more demanding professional boats, such as rescue boats or military inflatable boats, polyurethane materials or high-strength fabrics are more ideal choices. These boats often need to withstand greater water pressure and harsher environmental conditions, so the strength and durability of the fabric are key considerations.

Inflatable boats used in extreme sports or outdoor adventures often require tougher fabrics. Such inflatable boats must have high wear and impact resistance and be able to adapt to complex water environments and bad weather, so advanced polyurethane or high-strength composite materials would be a better choice.

The choice of fabric for an inflatable boat directly affects the performance and service life of the boat. With the advancement of material technology, modern inflatable boat fabrics are constantly improving to meet the needs of different users. From PVC to polyurethane to high-strength fiber materials, the selection of each fabric has its specific advantages and applicable scenarios. Whether it is leisure and entertainment or professional applications, choosing the right fabric can ensure that the inflatable boat performs well on the water and bring users a safer and more comfortable experience.

English

English русский

русский Français

Français Español

Español عربى

عربى