PVC Tarpaulin Fabric is rapidly emerging in multiple industries such as industry, agriculture, commerce and outdoor activities due to its excellent durability, versatility and wide range of applications. This high-performance composite material is changing the traditional fabric market and providing reliable and cost-effective solutions for various needs.

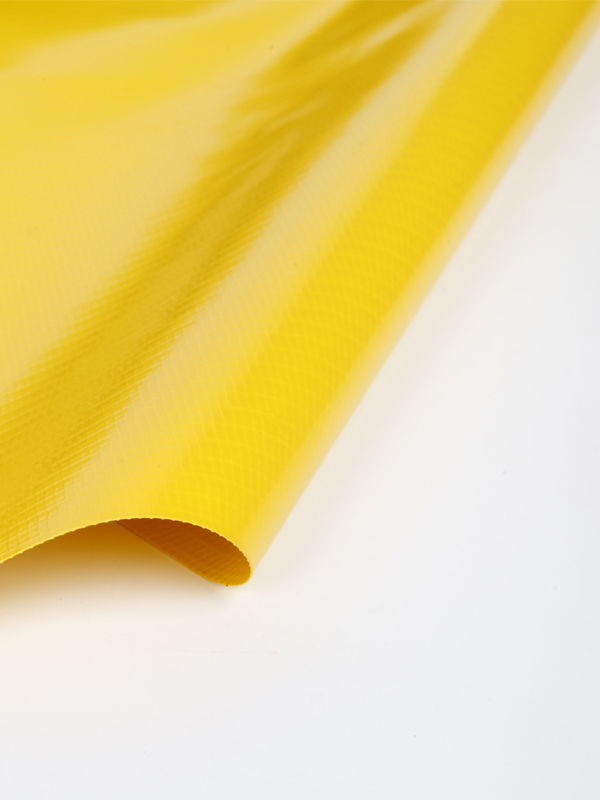

PVC Tarpaulin Fabric is a synthetic material made of polyester base fabric as the base material and coated with a polyvinyl chloride (PVC) layer on the surface. Its core features are waterproof, UV-resistant and tear-resistant properties, as well as good flexibility and weather resistance. This makes PVC tarpaulin an ideal covering, protection and separation material.

The PVC coating structure makes the tarpaulin have strong waterproof properties and can be used in harsh weather conditions to ensure that the cover is not damaged by rain.

The high tensile strength of the polyester base fabric gives the tarpaulin excellent tear resistance, which is suitable for high-load and high-friction scenarios.

The PVC coating prevents fabric aging, prolongs its service life, and remains stable even in high or low temperature environments.

PVC tarpaulins can be used as industrial protective covers, advertising spray painting materials, and even perform well in home sunshade and agricultural covering.

Its flexible customizability meets the special requirements of different users for size, thickness, color and pattern.

PVC tarpaulins with anti-UV coating can still maintain bright colors after long-term exposure outdoors. Flame retardant treatment makes it safer in construction sites or special industrial scenes.

PVC tarpaulins have low production costs and high reuse rates, making them extremely cost-effective materials.

With the improvement of environmental protection processes, many PVC tarpaulin products meet green production standards.

PVC tarpaulins are widely used in the transportation and storage protection of goods, such as truck tarpaulins and container covers, which can effectively prevent goods from getting damp and damaged.

In industrial facilities, PVC tarpaulins are often used as dust and rain covers for large equipment to provide all-weather protection. In the field of agricultural covering, PVC tarpaulins can be used to protect crops from wind, rain and pests, while maintaining a suitable temperature and humidity in the shed.

In horticultural scenes, PVC tarpaulins are often used as covering materials for greenhouses to protect against sun and heat. PVC tarpaulin is the main material for camping tents, carports, and awnings, and is widely favored for its durability and portability.

PVC tarpaulin has become the preferred material for various exhibitions, temporary event venues, and outdoor advertising spray painting canvases due to its high-definition printing effect and waterproof performance.

In emergency situations, PVC tarpaulin is widely used to make simple shelters, waterproof awnings, and medical tents, and is a key material in disaster relief.

With the advancement of science and technology, the production technology of PVC tarpaulin has become more mature, and innovative elements are constantly being incorporated:

By improving the base fabric and coating materials, manufacturers have launched lighter but stronger PVC tarpaulin products that are easy to transport and install. New environmentally friendly PVC coatings have greatly reduced the emission of harmful substances, making PVC tarpaulin more in line with the trend of sustainable development.

PVC tarpaulins with intelligent temperature control and automatic dimming functions are gradually emerging, bringing more application possibilities to the agricultural and construction fields.

Advanced digital printing technology allows PVC tarpaulin to have higher pattern resolution and color saturation, providing more exquisite visual performance for advertising and brand promotion.

According to industry research reports, the global PVC tarpaulin market size is expected to continue to expand at an average annual growth rate of more than 5% in the next five years. The Asia-Pacific region has become the main growth driver of the product due to the booming logistics and construction industries.

Although PVC tarpaulin fabrics have many advantages, they are also facing competitive pressure from other new materials, such as coated polyurethane (PU) fabrics and silicone coating materials. In order to maintain market competitiveness, companies need to continuously optimize production processes, reduce costs, and promote more environmentally friendly PVC tarpaulin products.

PVC tarpaulin fabrics have shown great potential in applications in various industries with their unparalleled versatility and high cost-effectiveness. Whether it is industrial protection, agricultural development, or support for outdoor activities, PVC tarpaulins provide trustworthy solutions. In the future, with the in-depth development of environmental protection technology and intelligent materials, PVC tarpaulin fabrics will surely occupy a more important position in the global market and provide more innovation and convenience for modern life.

English

English русский

русский Français

Français Español

Español عربى

عربى