As a light, flexible and easy-to-carry water transportation tool, inflatable boats are widely used in leisure and entertainment, rescue operations and military purposes. The core material of inflatable boats, inflatable boat fabric, is the key to its performance and durability.

The multi-layer structure design of inflatable boat fabric enables it to meet multiple functional requirements:

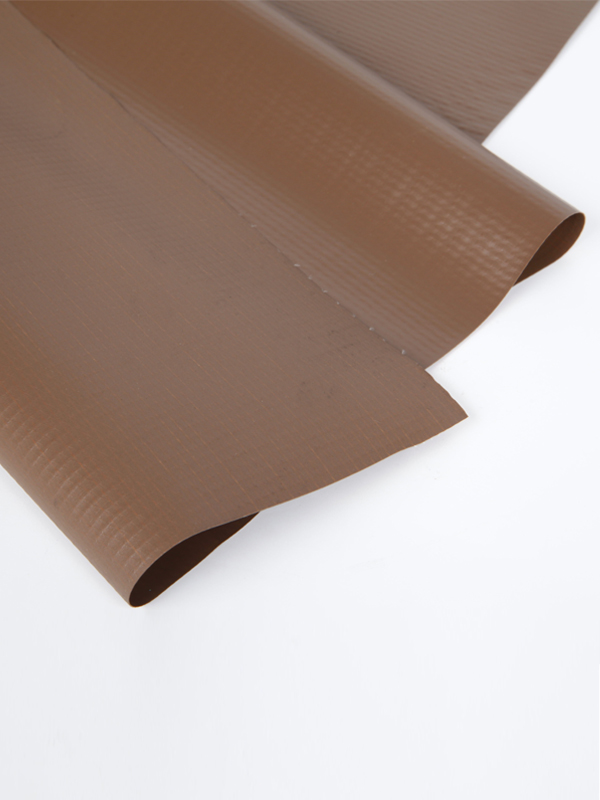

Outer protective film

The outer layer is usually coated with polyurethane (PU) or polyvinyl chloride (PVC), which has waterproof, UV-resistant and aging-resistant properties. This layer is in direct contact with the external environment and needs to withstand the test of sun exposure, seawater erosion and friction.

Intermediate reinforcement layer

The reinforcement layer is usually made of high-strength fiber fabrics, such as polyester or nylon. These fibers are treated with a special weaving process to form a dense grid structure, giving the fabric excellent tensile strength and tear resistance.

Inner airtight layer

The inner layer is responsible for maintaining airtightness and is usually made of thermoplastic polyurethane (TPU) or other polymer materials. This material has an extremely low gas permeability, ensuring that the inflatable boat remains inflated for a long time.

Production process

The production process of inflatable boat fabrics combines modern textile technology and composite material processing technology, and mainly includes the following steps:

Fiber weaving

The base fabric is made of high-strength fibers through weaving or knitting processes, which is the basic structure of the fabric.

Coating treatment

One or more functional coatings, such as PVC, PU or TPU, are applied to the surface of the base fabric. The thickness and uniformity of the coating directly affect the performance of the fabric.

Lamination

The different functional layers are compounded together through high temperature and high pressure processes to form an integrated multi-layer structure.

Finishing

The fabric is cut, sewn or welded to form the various components of the inflatable boat. In addition, mildew-proof, antibacterial or other functional treatments may also be performed.

Advantages of inflatable boat fabrics

Due to their unique structure and material selection, inflatable boat fabrics have the following significant advantages:

High strength and durability

The intermediate reinforcement layer gives the fabric extremely high tensile strength and tear resistance, enabling it to withstand complex underwater pressure and external impact.

Excellent airtightness

The inner airtight layer effectively prevents gas leakage, ensuring that the inflatable boat maintains stable performance during long-term use.

Strong weather resistance

The outer protective film can resist UV, salt spray corrosion and extreme temperature changes, extending the service life of the inflatable boat.

Lightweight design

Despite its excellent performance, the inflatable boat fabric still maintains a relatively light weight for easy transportation and storage.

Environmental protection potential

With the advancement of sustainable development, more and more manufacturers have begun to use recyclable materials or bio-based raw materials to produce inflatable boat fabrics to reduce the impact on the environment.

Application areas

Inflatable boat fabrics have been widely used in many fields due to their versatility:

Leisure and entertainment

In yacht clubs, lake tours and beach vacations, inflatable boats are favored for their portability and ease of operation, making them an ideal choice for family entertainment.

Water rescue

Inflatable boats are widely used in emergency tasks such as flood rescue and maritime search and rescue due to their rapid deployment and high buoyancy.

Military use

Military inflatable boats are often used for landing operations, material transportation and reconnaissance missions of special forces, requiring fabrics to have higher strength and concealment.

Fisheries and scientific research

Fishermen and researchers use inflatable boats for offshore operations or data collection, so the durability and corrosion resistance of fabrics are particularly important.

Environmental challenges and future prospects

Although inflatable boat fabrics have excellent performance, their production and disposal still face certain environmental challenges. For example, some coating materials may contain non-degradable chemical components, and the recycling rate of waste fabrics is low. To this end, the industry is actively exploring more environmentally friendly solutions, such as developing degradable coatings or using bio-based materials to replace traditional raw materials.

Looking to the future, with the advancement of technology, inflatable boat fabrics are expected to achieve higher performance breakthroughs. For example, the introduction of intelligent sensing technology can monitor the pressure and damage of fabrics in real time; the application of nanomaterials may further improve the strength and air tightness of fabrics. In addition, the popularization of green and environmental protection concepts will also drive the industry to develop in a sustainable direction.

Inflatable boat fabrics have become an important part of modern water transportation with their excellent performance and wide application. It not only provides safety for people's water activities, but also provides reliable solutions for rescue and military fields. In the future, with the continuous innovation of technology, inflatable boat fabrics will surely make greater progress in performance, environmental protection and intelligence, providing stronger support for water exploration and operations.

English

English русский

русский Français

Français Español

Español عربى

عربى